Mixed PCB Assembly Manufacturer

Mixed Assembly service refers to the process of assembling a printed circuit board (PCB) that incorporates both surface mount technology (SMT) components and through-hole components. As a Mixed PCB Assembly Manufacturer we provide Assembly that combines the advantages of both SMT and through-hole assembly techniques to accommodate a variety of component types and fulfill specific design requirements.

In mixed assembly, SMT components are typically used for smaller, more compact parts, while through-hole components are utilized for larger components or those that require additional mechanical stability or power handling capabilities. By combining these two assembly techniques, manufacturers can leverage the strengths of each method and achieve the desired functionality and performance for the PCB.

The mixed assembly process involves the following steps:

PCB Preparation

Design the PCB layout, including the placement of both SMT and through-hole component footprints. The PCB is usually designed with pre-drilled holes for the through-hole components and pads for the SMT components.

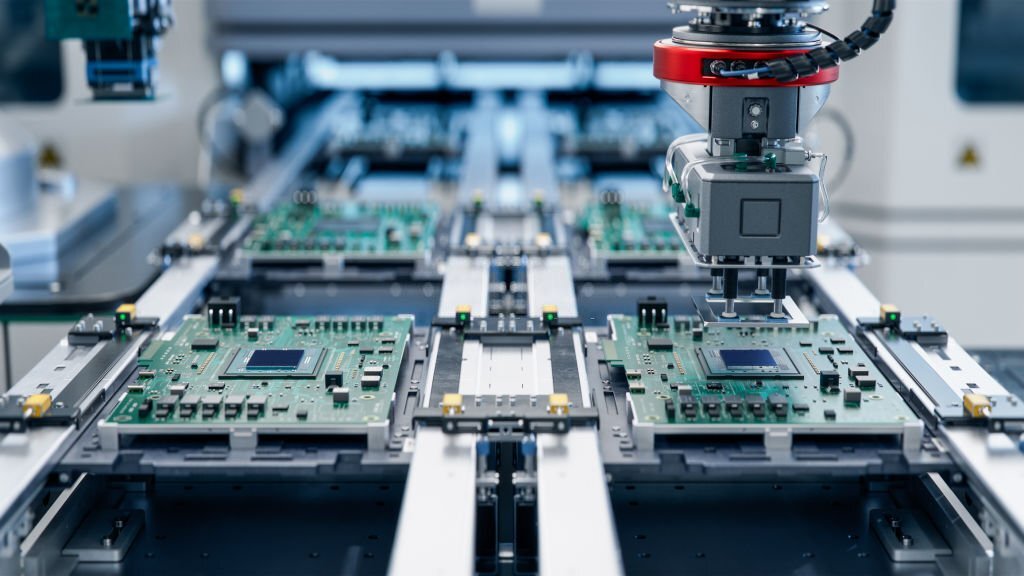

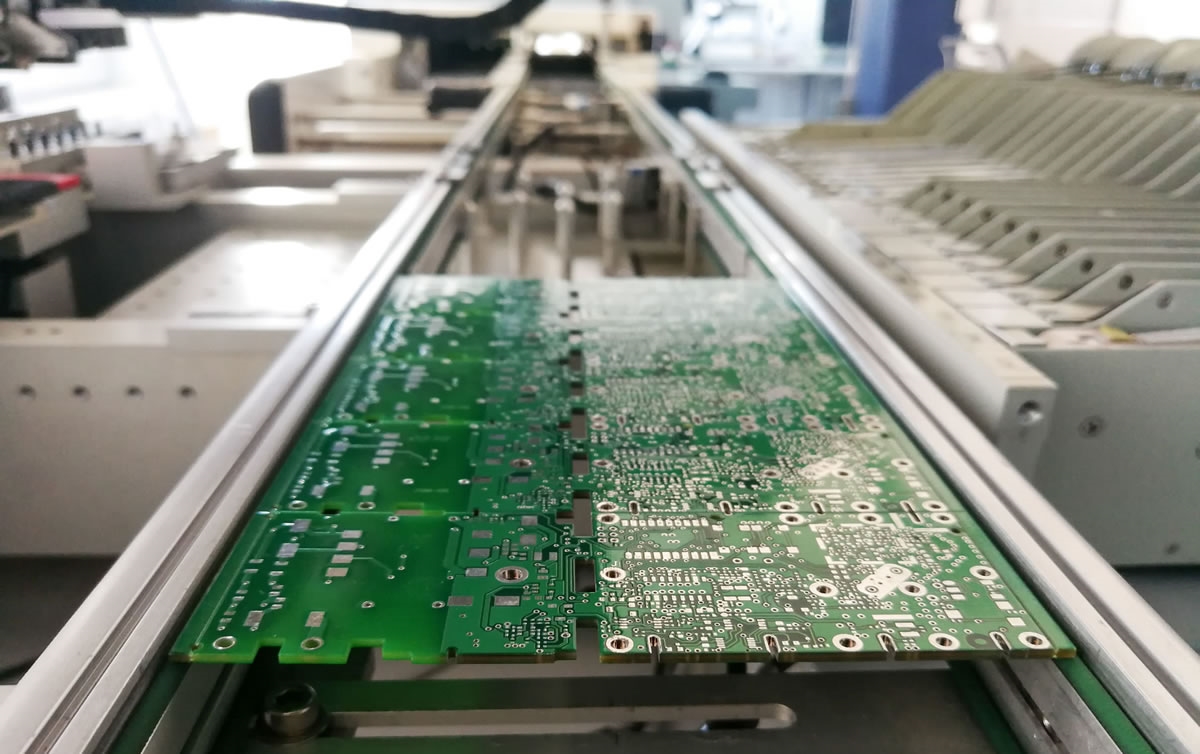

SMT Component Assembly

Use automated pick-and-place machines to accurately position and solder the SMT components onto the PCB. This includes the application of solder paste, component placement, and reflow soldering.

Through-Hole Component Insertion

Insert the leads or pins of the through-hole components into the pre-drilled holes on the PCB. The components are positioned on the top side of the PCB, and the leads extend through the holes to the bottom side.

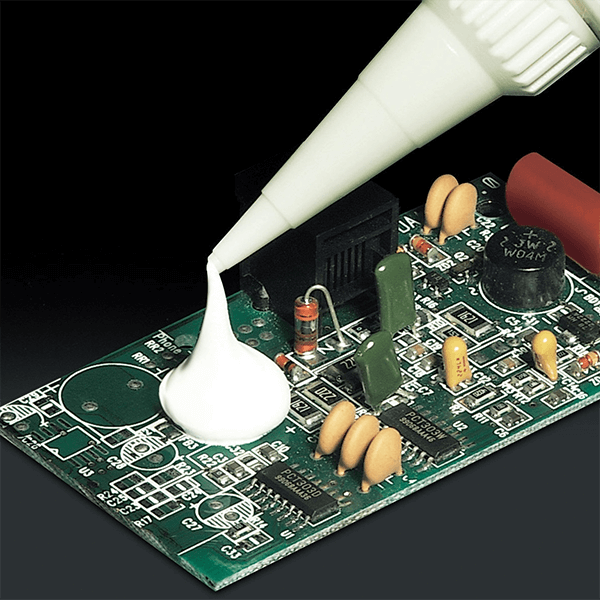

Component Securing

Secure the through-hole components in place on the top side of the PCB. This can be done using clips, adhesive, or mechanical fixtures to provide stability during the soldering process.

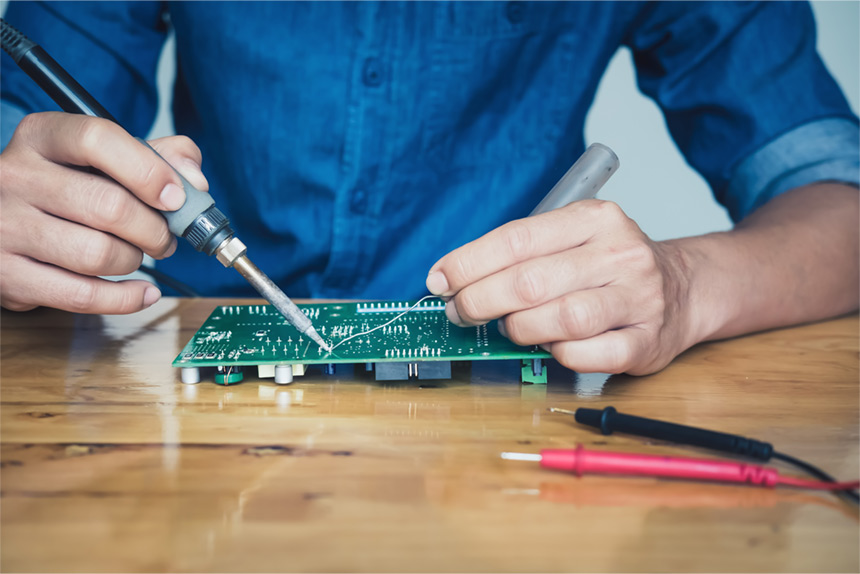

Soldering

Apply solder to the exposed leads on the bottom side of the PCB. This can be done manually by soldering iron or through wave soldering, selective soldering, or other appropriate techniques. The solder forms a connection between the through-hole component leads and the PCB pads.

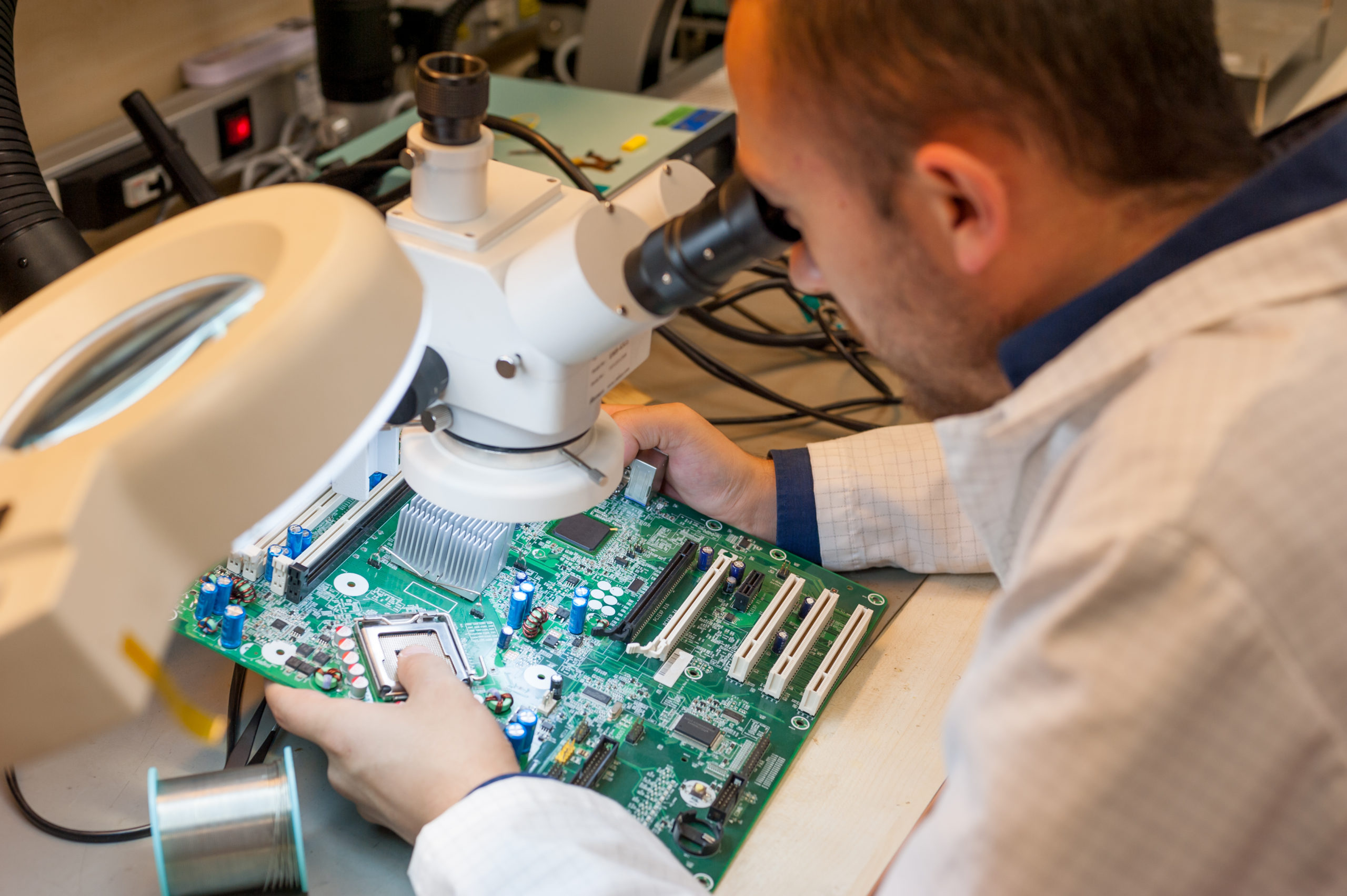

Inspection and Testing

Perform thorough inspection and testing procedures to ensure proper solder joints, component alignment, and functionality. This may include visual inspection, automated optical inspection (AOI), in-circuit testing (ICT), or functional testing.

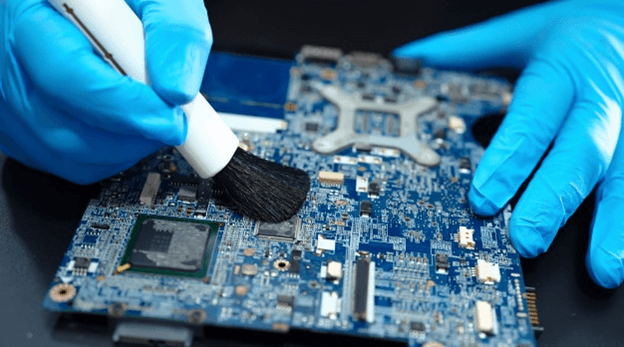

Cleaning

Clean the PCB to remove any flux residue or contaminants that may have been left behind during the soldering process. This step ensures the long-term reliability of the assembled PCB.

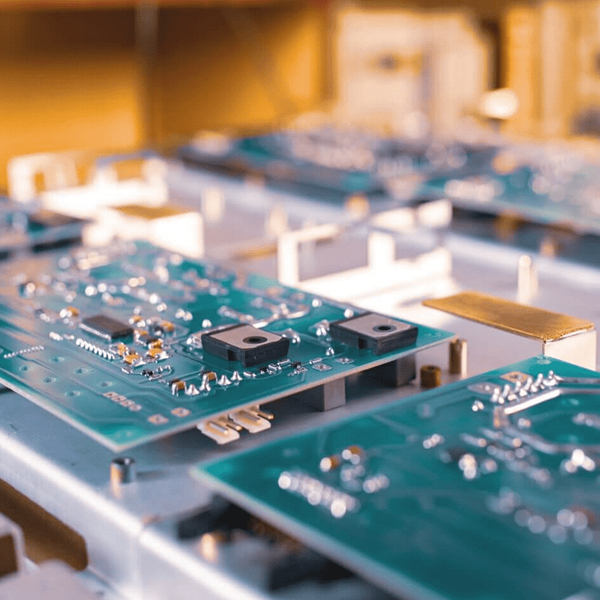

Final Inspection and Packaging

Conduct a final inspection to verify the overall quality of the mixed assembly. Once the PCBs pass inspection, they are packaged according to the customer’s specifications and prepared for distribution.

Mixed Assembly services are commonly used in various industries, including automotive, aerospace, telecommunications, industrial equipment, and consumer electronics. By combining SMT and through-hole assembly techniques, manufacturers can achieve the desired functionality, reliability, and performance for PCBs with diverse component types and applications.

Reach out to Epsilon Electronics for your next Mixed PCB Assembly requirements.

Email Us

pcb@epsilonelectronics.in

Call US

+91 98796 26181 / 079-4800-2842

Related Other Services

BOM Sourcing

BOM Sourcing

BOM sourcing service refers to a service that assists in the procurement of Bill of Materials (BOM) components for manufacturing or product assembly.

SMT PCB Assembly

SMT PCB Assembly

SMT (Surface Mount Technology) PCB Assembly is a method of assembling electronic circuits on printed circuit boards (PCBs).

Through Hole Assembly

Through Hole Assembly

Through-hole PCB Assembly is a method of assembling electronic circuits on printed circuit boards (PCBs) using through-hole components.

Turn Key PCB Assembly

Turn Key PCB Assembly

Turnkey PCB Assembly service refers to a comprehensive service provided by a manufacturing company or assembly house where they handle...