Flexible PCBs, with their ability to conform to non-planar surfaces and withstand dynamic conditions, offer unparalleled versatility in modern electronics. However, their assembly poses unique challenges that demand specialized approaches and expertise. In this blog post, we’ll delve into the key challenges encountered in flexible PCB assembly and explore strategies to overcome them.

Material Handling:

- Delicate Nature: Flexible PCB materials require careful handling to prevent damage such as tears or creases.

- Specialized Equipment: Investing in equipment designed for handling flexible substrates is essential to minimize the risk of damage during assembly.

Component Placement:

- Precision Placement: Ensuring accurate component placement on flexible substrates is critical for functionality and reliability.

- Challenges of Flexibility: The inherent flexibility of the substrate can make precise placement more challenging compared to rigid boards.

Soldering Techniques:

- Temperature Control: Maintaining precise temperature profiles during soldering processes is crucial to avoid damaging the flexible substrate.

- Specialized Techniques: Laser soldering and conductive adhesives may be employed to mitigate the challenges associated with traditional reflow soldering.

Mechanical Stability:

- Design Considerations: Designing flexible PCB assemblies to withstand mechanical stresses such as bending or flexing requires careful consideration of factors like bend radius and flex life.

- Testing and Validation: Rigorous mechanical testing is necessary to ensure the reliability of flexible assemblies under dynamic conditions

Thermal Management:

- Limited Thermal Conductivity: Flexible substrates may have lower thermal conductivity than rigid boards, necessitating effective thermal management strategies.

- Heat Dissipation Solutions: Incorporating features such as heat sinks, thermal vias, or designing for improved airflow can help mitigate thermal challenges.

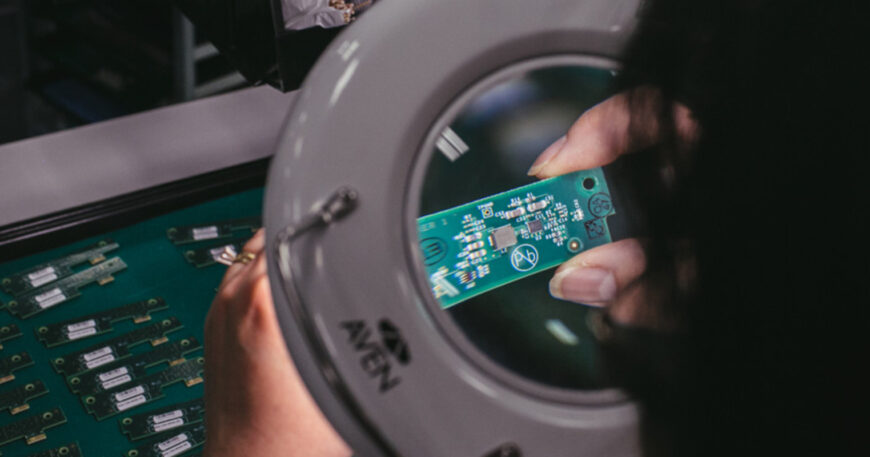

Testing and Inspection:

- Specialized Testing Equipment: Traditional testing methods like AOI may be less effective on flexible substrates, requiring the use of specialized equipment for quality assurance.

- Comprehensive Testing Protocols: Developing robust testing protocols tailored to the unique characteristics of flexible PCBs is essential to ensure reliability.

Environmental Considerations:

- Enhanced Environmental Resilience: Flexible PCB assemblies may be subjected to harsh environmental conditions, necessitating the selection of materials and design features to enhance durability.

- Compliance Standards: Meeting regulatory requirements for environmental resilience ensures the suitability of flexible assemblies for diverse applications.

Conclusion

Navigating the complexities of flexible PCB assembly requires a combination of specialized knowledge, equipment, and processes. By understanding and addressing key challenges such as material handling, component placement, soldering techniques, mechanical stability, thermal management, testing, and environmental considerations, manufacturers can deliver reliable and high-quality flexible PCB assemblies tailored to the needs of modern electronics applications.Reach out to Epsilon Electronics for Turnkey PCB Assembly, Hardware Manufacturing, EMS Channel Partner for your electronics production requirements. We are one of the trusted EMS Solution providers in the Gujarat region with integrated services of functional testing, box building etc.

Contact Details:

Call Us: +91 9879 6261 81

Email: pcb@epsilonelectronics.in

Web: www.mfg.epsilonelectronics.in