Surface Mount Technology PCB Assembly

SMT (Surface Mount Technology) PCB Assembly is a method of assembling electronic circuits on printed circuit boards (PCBs). It is a widely used technique in the electronics manufacturing industry.

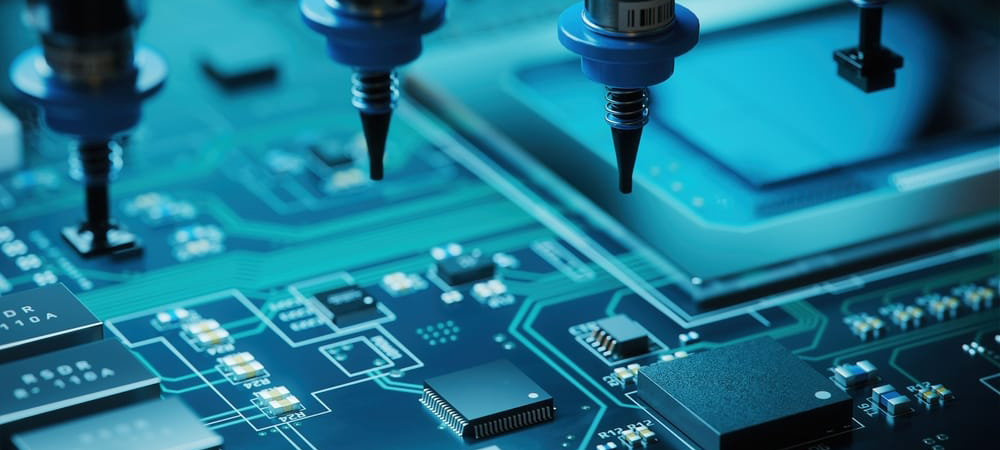

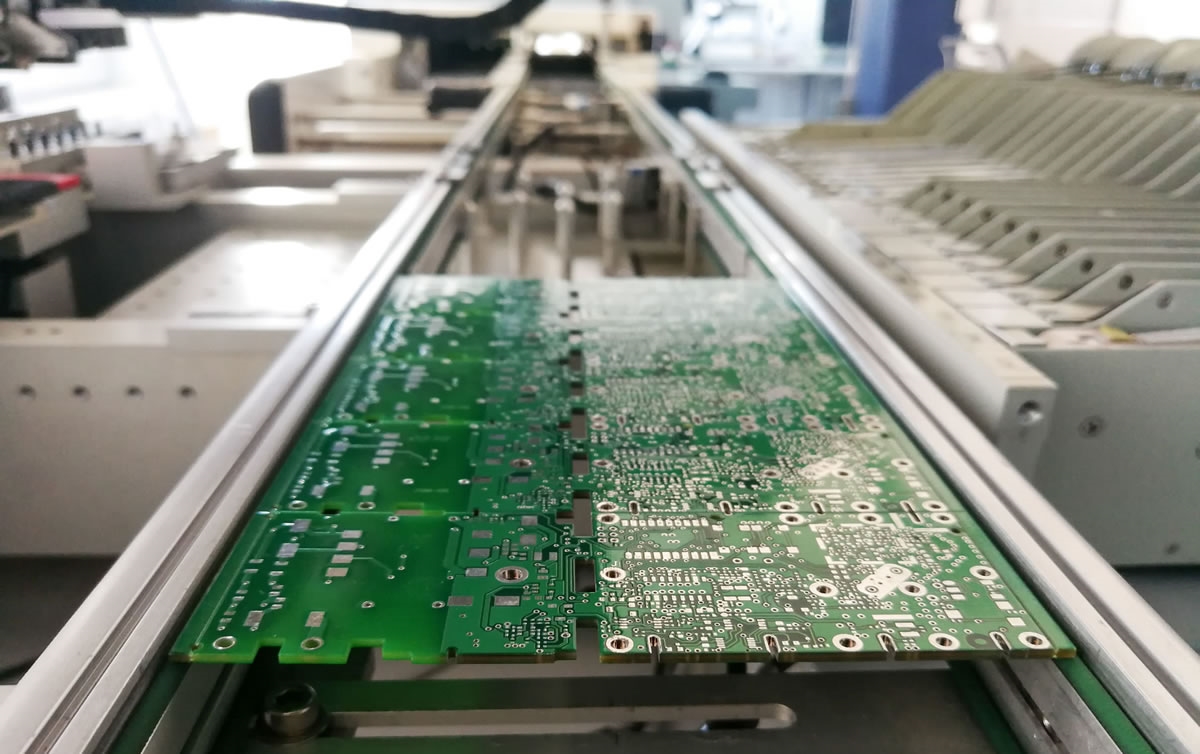

In SMT PCB Assembly, electronic components are mounted directly onto the surface of the PCB using automated assembly equipment. These components are typically smaller and have a higher component density compared to through-hole components, which are inserted into pre-drilled holes on the PCB.

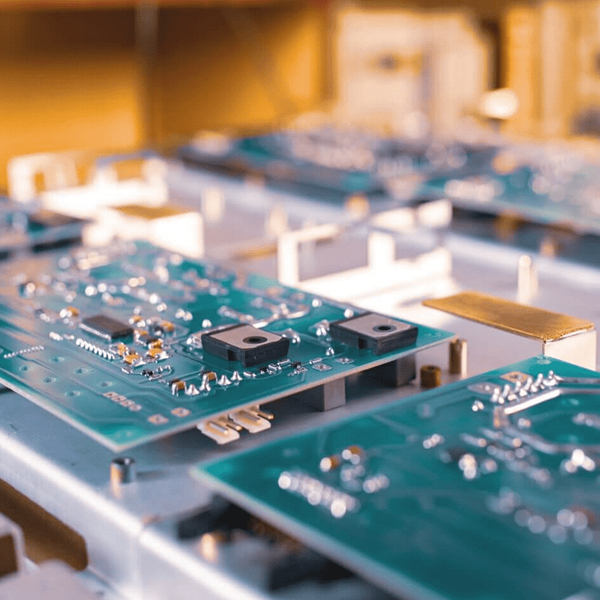

The process begins with a bare PCB, which has copper traces and pads to which the components will be soldered. The PCB is first coated with a solder paste, a sticky mixture of flux and tiny solder balls. The solder paste is applied to the pads using a stencil, which has openings corresponding to the component footprints on the PCB.

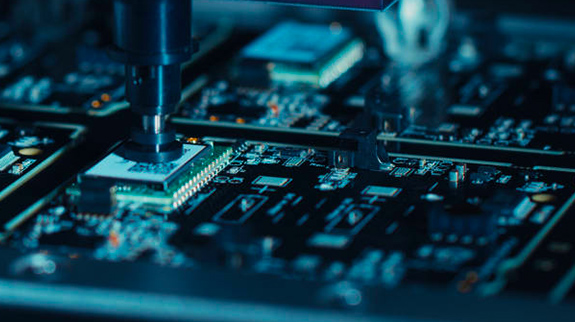

Once the solder paste is applied, the components are placed on their respective footprints using pick-and-place machines. These machines are capable of high-speed and precise component placement. The components are held in position by the sticky solder paste.

After the components are placed, the PCB is passed through a reflow oven. The oven heats the PCB to a specific temperature, causing the solder paste to melt and form a bond between the components and the PCB pads. The molten solder reflows and solidifies during the cooling process, creating reliable electrical connections.

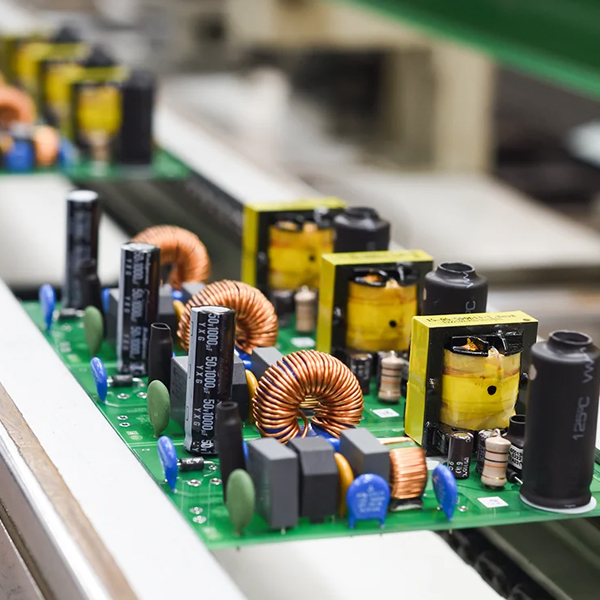

SMT PCB Assembly India offers several advantages over through-hole assembly. It allows for smaller and lighter electronic devices, improved manufacturing efficiency, and better electrical performance due to shorter signal paths. SMT technology also enables the use of automated assembly processes, reducing labour costs and increasing production speed.

Overall, SMT PCB Assembly has become the dominant method for electronic circuit assembly due to its versatility, efficiency, and compatibility with modern electronic components.

Design PCB

Create the PCB layout design, including component placement and routing of traces.

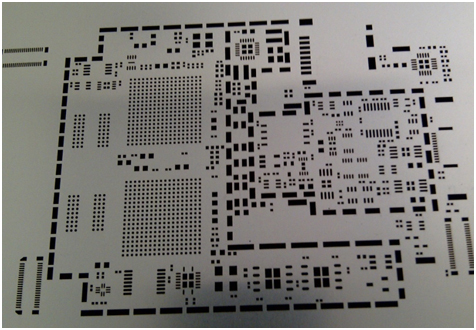

Stencil Creation

Design and manufacture a stencil with openings corresponding to the component footprints on the PCB.

Solder Paste Application

Place the stencil over the PCB and apply solder paste onto the exposed pads using a squeegee or a solder paste dispenser.

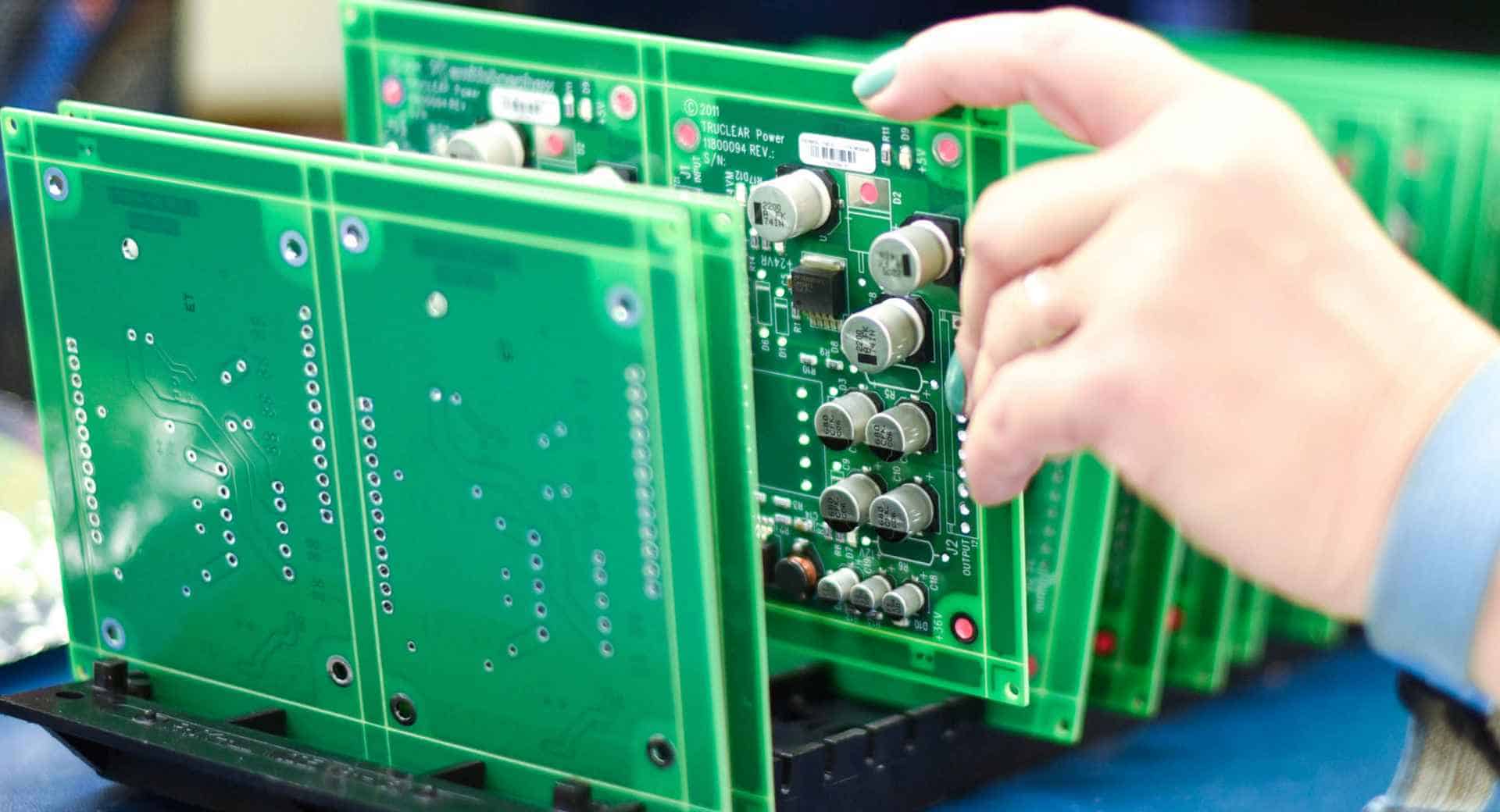

Component Placement

Use automated pick-and-place machines to accurately position the surface mount components onto the solder paste-covered pads.

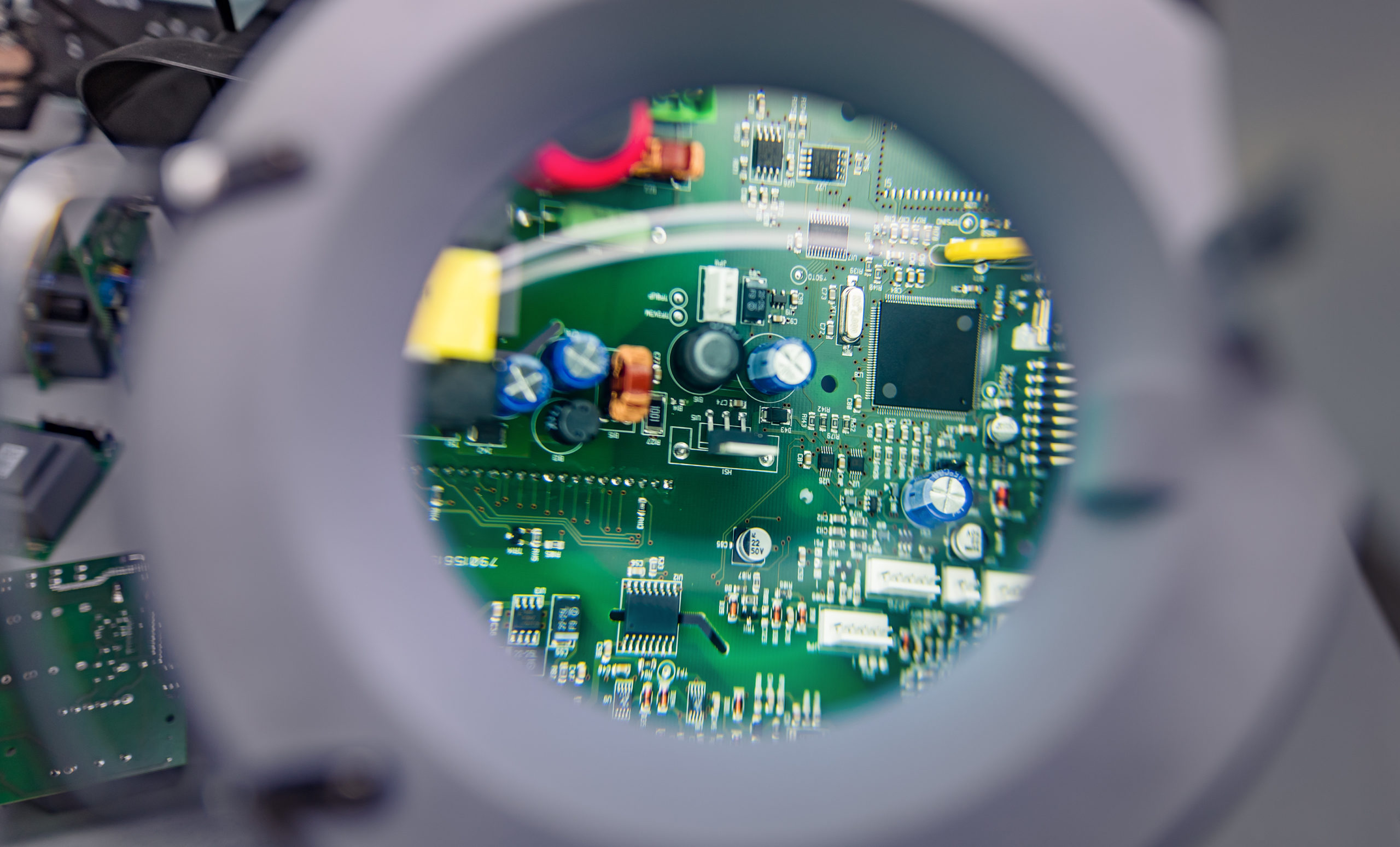

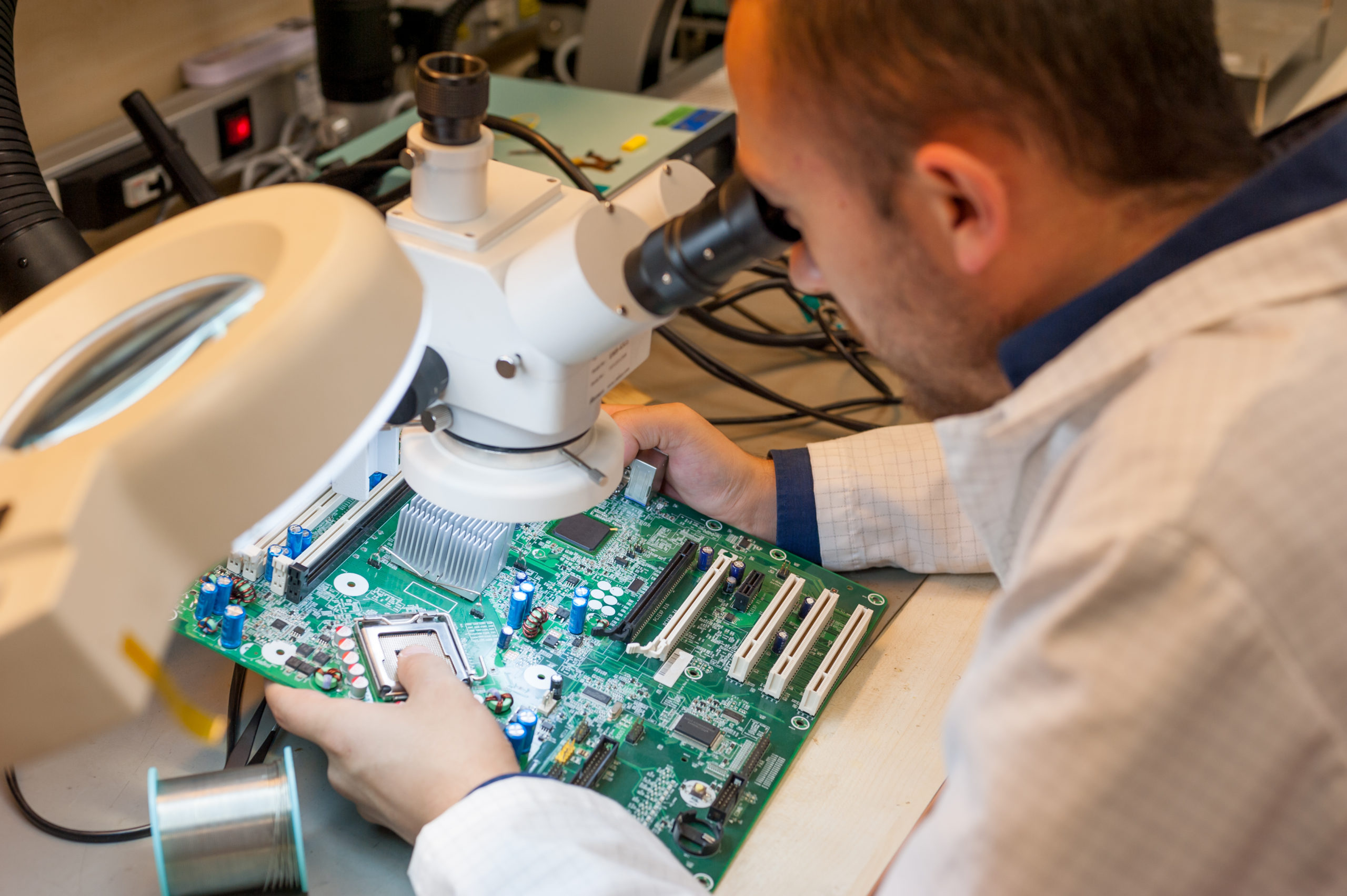

Inspection

Perform an automated or manual inspection to ensure correct component placement, orientation, and absence of defects.

Reflow Soldering

Pass the PCB through a reflow oven where it goes through a carefully controlled heating process. The solder paste melts, creating electrical connections between the components and the PCB.

Inspection and Testing

Conduct a thorough inspection of the solder joints and perform functional testing to ensure proper functionality of the assembled PCB.

Cleaning

Clean the PCB to remove any flux residue or contaminants that may have been left behind during the soldering process.

Secondary Assembly

If necessary, additional components such as through-hole components or connectors may be added using through-hole assembly techniques.

Final Inspection

Perform a final inspection to ensure the quality and reliability of the assembled PCB, including visual inspection and testing.

Packaging

Package the assembled PCBs according to the specific requirements, which may include antistatic packaging, labeling, and protective measures.

Distribution

Ship or distribute the assembled PCBs to their intended destinations.

Reach out to Epsilon Electronics for your next SMT PCB Assembly requirements.

Email Us

pcb@epsilonelectronics.in

Call US

+91 98796 26181 / 079-4800-2842

Related Other Services

BOM Sourcing

BOM Sourcing

BOM sourcing service refers to a service that assists in the procurement of Bill of Materials (BOM) components for manufacturing or product assembly.

Through Hole Assembly

Through Hole Assembly

Through-hole PCB Assembly is a method of assembling electronic circuits on printed circuit boards (PCBs) using through-hole components.

Turn Key PCB Assembly

Turn Key PCB Assembly

Turnkey PCB Assembly service refers to a comprehensive service provided by a manufacturing company or assembly house where they handle...

Mixed Assembly

Mixed Assembly

Mixed Assembly service refers to the process of assembling a printed circuit board (PCB) that incorporates both surface mount technology...