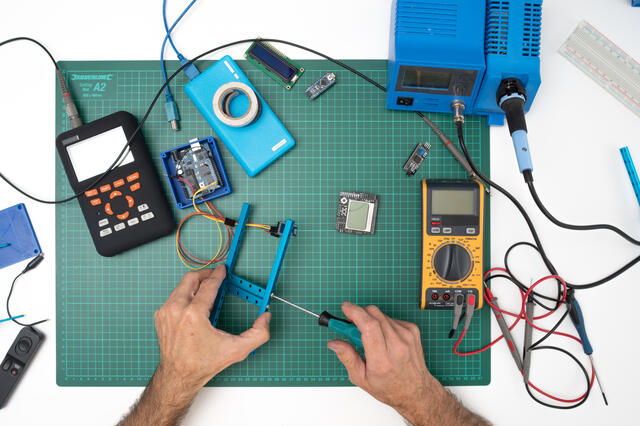

BOX Building Service

BOX building service, also known as Box Build Assembly, refers to the process of integrating various electronic components and sub-assemblies into a complete enclosure or system-level assembly. It involves the assembly of the entire product, including the PCB, mechanical components, wiring, connectors, displays, buttons, and any other necessary elements, into a finished and functional unit.

Box building service typically follows the completion of PCB assembly and involves the following steps:

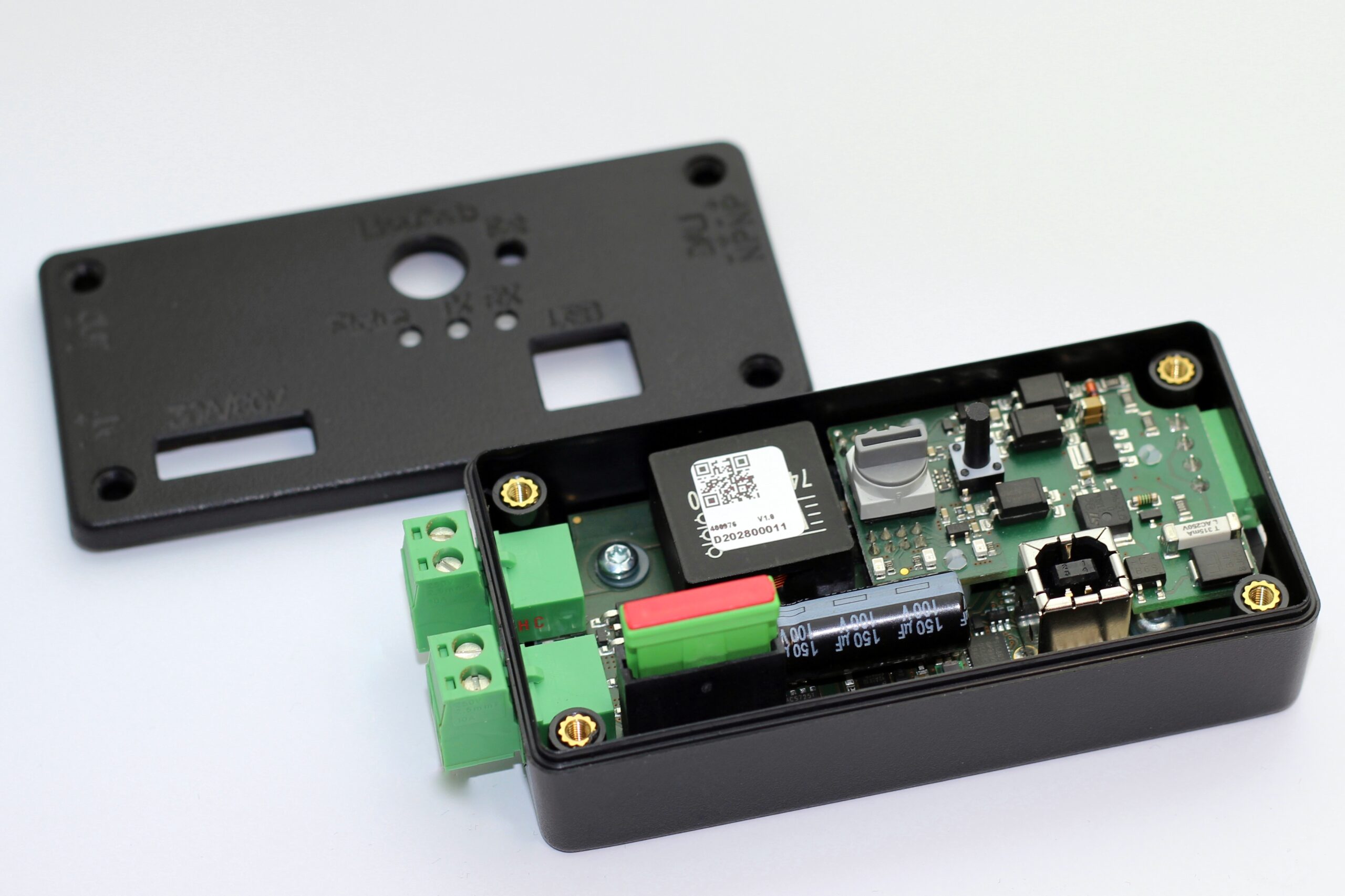

Enclosure Selection

Choose an appropriate enclosure or housing for the product. The enclosure may be custom-designed or selected from existing off-the-shelf options, depending on the specific requirements of the product.

Mechanical Assembly

Mount the PCB onto the enclosure, ensuring proper alignment and secure attachment. This may involve using screws, brackets, or other fastening methods to secure the PCB in place.

Wiring and Cable Assembly

Connect the necessary wires and cables to the PCB, ensuring proper routing, strain relief, and connection to external components or interfaces. This includes connecting power cables, signal cables, data cables, and any other required wiring.

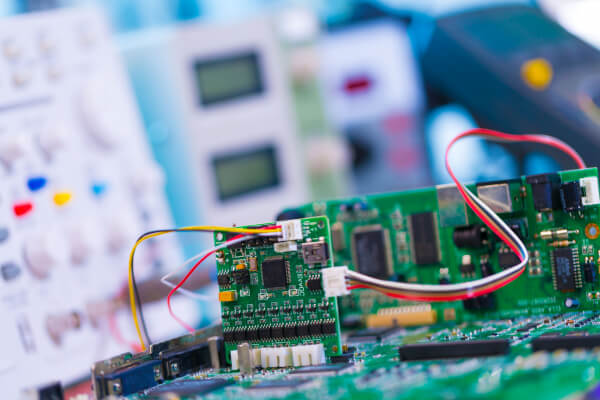

Component Integration

Install and integrate additional components such as displays, buttons, switches, connectors, sensors, or modules as specified by the product design. These components are mounted and connected within the enclosure to achieve the desired functionality.

Testing and Quality Control

Perform thorough testing and quality control procedures on the assembled box build unit to ensure proper functionality, adherence to specifications, and compliance with regulatory requirements.

Final Assembly and Finishing

Complete any remaining assembly steps, such as attaching covers, labels, logos, or other finishing touches to the product. This includes ensuring that all components are properly aligned and secured within the enclosure.

Packaging and Shipping

Package the fully assembled and tested products according to the specific requirements, including protective packaging, labelling, and documentation. The finished units are then prepared for shipping or distribution to customers or end-users.

Box building service is often provided by contract manufacturers or assembly houses that specialize in integrating electronic components into complete systems. It offers the advantage of streamlining the manufacturing process, reducing time-to-market, and ensuring a high level of quality and consistency in the final product.

Reach out to Epsilon Electronics for your next Box Building Solution requirements.

Email Us

pcb@epsilonelectronics.in

Call US

+91 98796 26181 / 079-4800-2842

Related Other Services

BOM Sourcing

BOM Sourcing

BOM sourcing service refers to a service that assists in the procurement of Bill of Materials (BOM) components for manufacturing or product assembly.

SMT PCB Assembly

SMT PCB Assembly

SMT (Surface Mount Technology) PCB Assembly is a method of assembling electronic circuits on printed circuit boards (PCBs).

Through Hole Assembly

Through Hole Assembly

Through-hole PCB Assembly is a method of assembling electronic circuits on printed circuit boards (PCBs) using through-hole components.

Turn Key PCB Assembly

Turn Key PCB Assembly

Turnkey PCB Assembly service refers to a comprehensive service provided by a manufacturing company or assembly house where they handle...